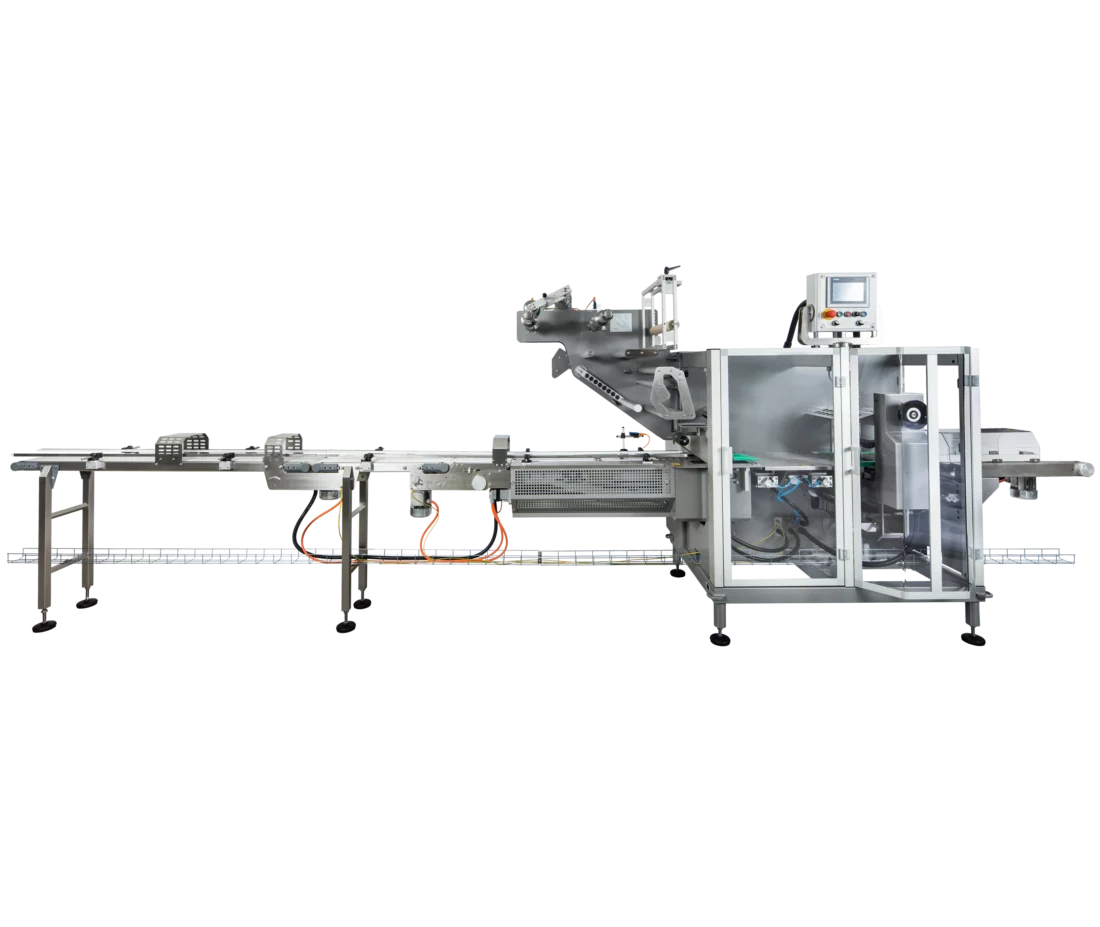

The Barsch flowpack packaging machines are designed for packing irregular product in a so-called flowpack film. The major advantages of this method of packaging are better hygiene, ease of use, speed and longer shelf life of the product.

- Maximum accessibility and easy maintenance

- Simple and intuitive operation with digital support and recipe management.

- Quick format change

- Robustly built

- Models in undersealer, top sealer, box-motion

Barsch produces flowpack machines in different versions, specifically tailored to your packaging needs. There is the horizontal flowpack machine with film feed from above and below, with rotating chisels or with box-motion technology. Which variant is suitable for which product depends on the packaging form and the product.

Barsch undersealers

These horizontal flow packers are usually used for packing products in trays, where the seal seam is on the underside. Examples are tomatoes, pears, mushrooms, etc. Also loose products such as stoplight packages for peppers and apples can be processed with these flexible machines.

Barsch top sealers

Top sealers are mainly used for packaging loose and irregular product. With these machines, the film feed is from below and the package is sealed at the top. Examples of products packed with our top sealers are: chicory, asparagus, rhubarb, carrots, lettuce and herbs.

My name is Matty. I am happy to help you with all your questions.

I am happy to help you with all your packaging questions! Do you have a question about a specific product? I am ready to support you and give more insight into our machines.

Or prefer direct advice? +31 (0) 166 700 215

Barsch flowpackers

For over 35 years, Barsch has been developing flowpack machines to pack products in flowpacks. Their flexible packaging solutions are suitable for a variety of products from fresh produce to Ready Meals, Convenience, Meat & More.